Professional lubrication of wind turbines thanks to simalube

Every wind turbine has a multitude of lubrication points which have to be supplied at regular intervals. Since wind turbines are often located in remote locations, maintenance and the related lubrication is associated with a great deal of time and expense. Extreme temperature fluctuations, humidity and moisture are heavy burdens on every wind turbine. In order to prevent the resulting damage, optimum lubrication is indispensable. With the simalube lubrication system, wind farm operators can minimize the risk of downtime and also increase the efficiency of their wind turbines.

Lubrication points

Challenges

- High demands on the availability of the systems

- Large seasonal temperature fluctuations

Solution

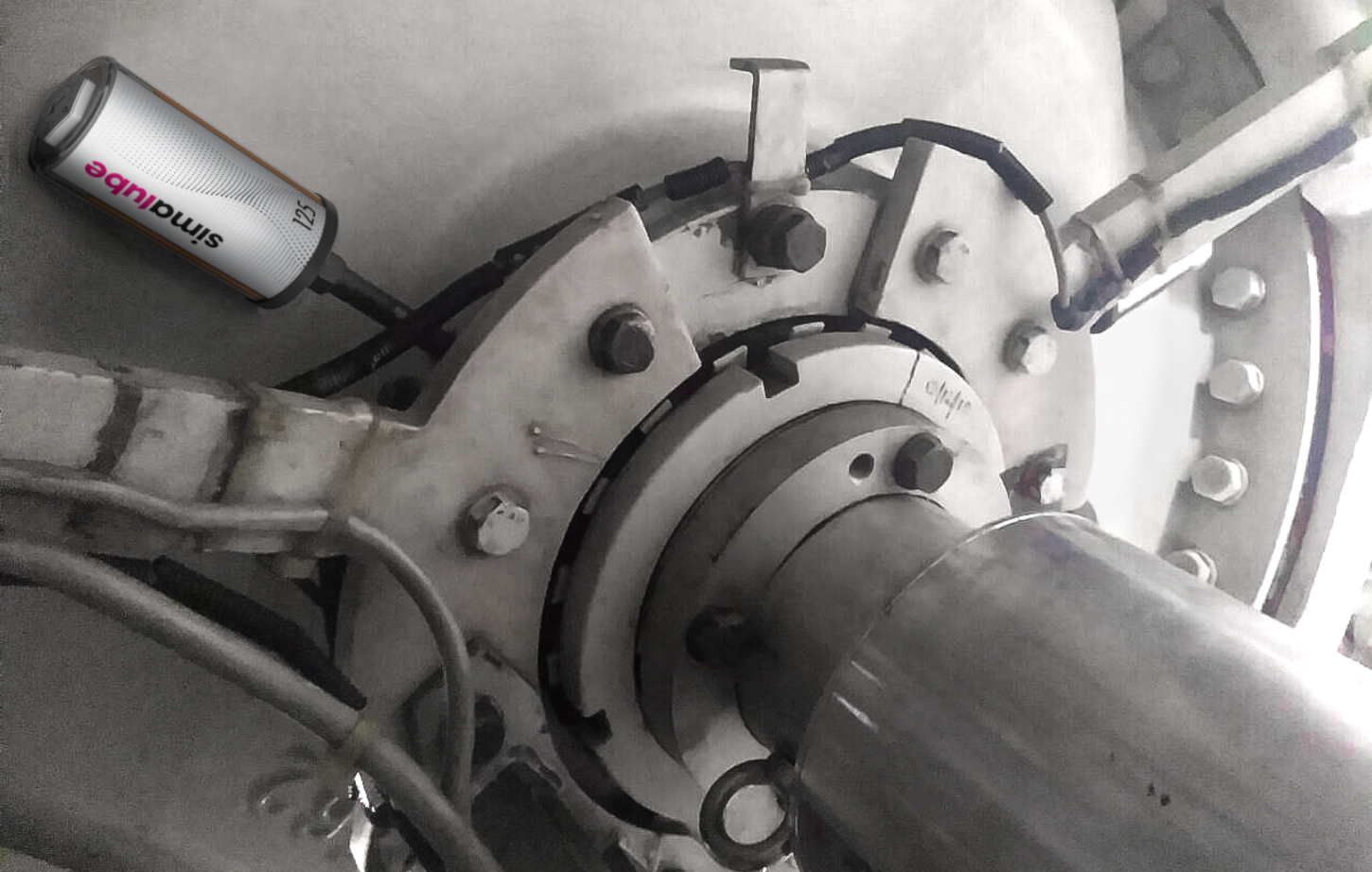

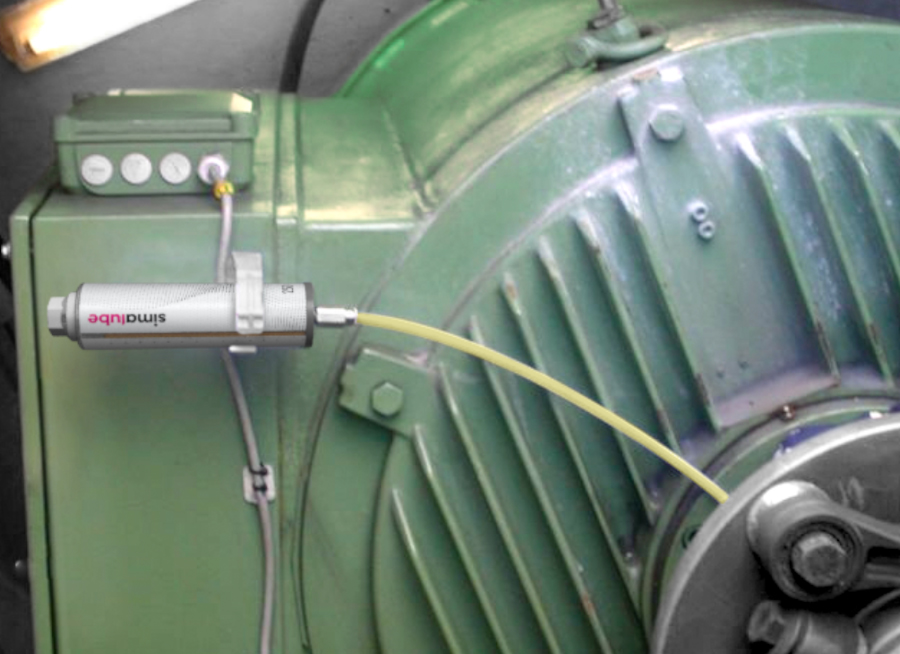

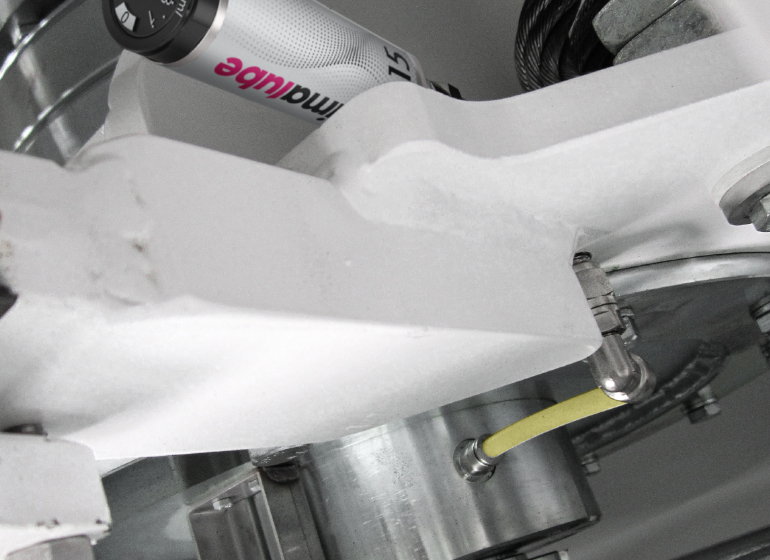

- simalube 60, 125 and 250 ml

- Installation direct, the lubricant is often supplied to the lubrication point via a lubrication pinion

Areas of application and advantages

simalube areas of application for wind turbines

- Rotor blade adjustment

- Rotor blade bearings

- Generator

- Yaw drive

- Gearboxes

- Pitch adjustment (variable speed gear unit)

- Main bearings

The benefits from automatic lubrication

- Increased operational safety

- Reduced downtime

- Constant supply of hard to reach lubrication points

- Less time spent on maintenance

- Reduction of wear and longer life of the components

Advantages of the simalube lubrication system

- Reduction of service requirements and maintenance costs (manual lubrication is no longer necessary, thus there is less required labour and the time savings are great)

- It is not necessary to shut down the machines during maintenance

- Longer service life of machines thanks to continuous and precise lubrication

- Flexibility: The running time is adjustable from 1–12 months

- Only one type of lubricator is needed per application. This allows a reduction of storage costs

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.